When investing in grow lights, it is important to think long-term. Two key considerations should be made when you purchase grow lights: What kind of yields can a light produce? How much does it cost to operate? Smart cultivators understand that their profit is determined by the size and quality of their crop minus the expenses of consumables like electricity, fertilizer, clones, etc.

An important concept to understand is that higher light density leads to greater yields, which creates more profit per harvest— and LEDs achieve this while also saving money by lowering operating costs compared to HPS/CMH lights. By switching to higher output and more efficient LED horticulture lighting, you can save hundreds of dollars per light per year.

How PPFD (Light Density) Affects Yield & Profit

There will be significant increases in plant growth (yield) as the light density increases up to a PPFD of 1500, then it plateaus or can even start to have an adverse effect. VOLT Grow® FL-1 can achieve an average PPFD of 1027 in a 4’x4′ area, which beats competitors like the Gavita 1700e, which only creates a PPFD of 912 over the same area.

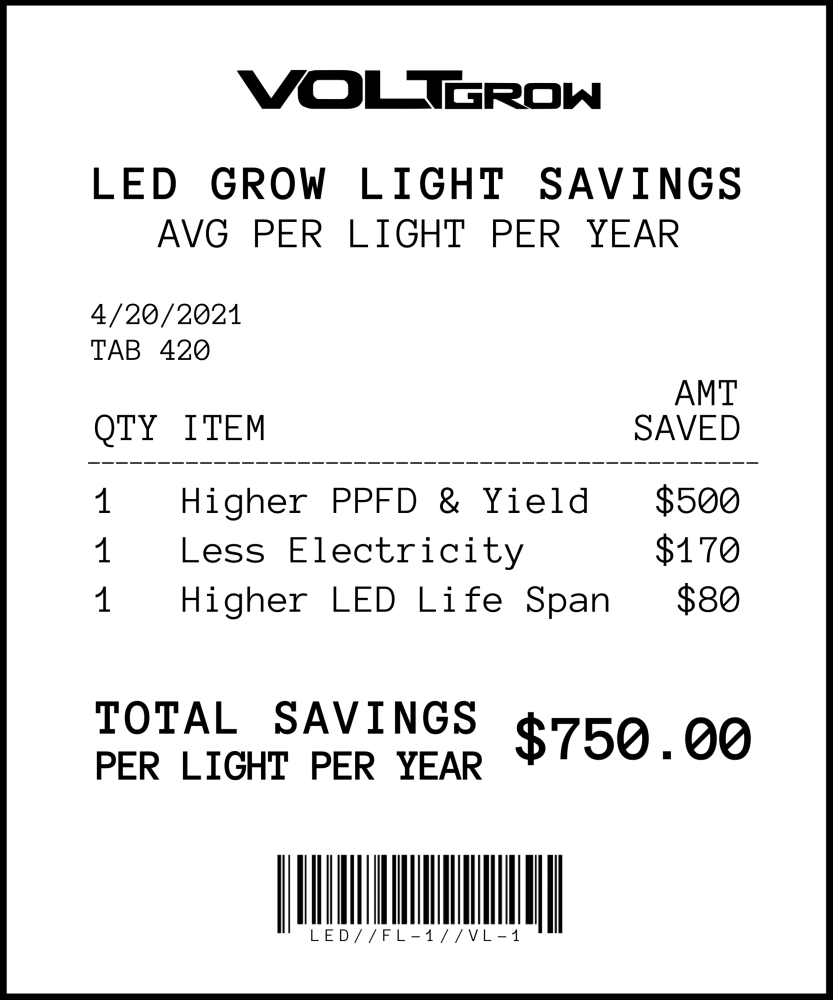

In practice, the exact change in yield will vary depending on several factors – but when all factors are left the same, growers will be able to achieve higher yields when light density increases. Just as an example, a 10 percent increase in yield from 1lb to 1.1lb per light with a sale price of $1000/lb will increase profit by $100 per light per harvest. Typically a couple of months between harvests, that is an extra profit of $500-600 per light per year.

How Switching To LED From HPS Lowers Operating Costs

LEDs have a life expectancy of 50,000 hours, which means they can have close to 10 years of use, while the lamps used in HPS grow lights are typically swapped after only 8-12 months of use. Not having to manage this upkeep saves a grower around $80 per light per year.

Additionally, the energy cost of VOLT Grow®’s 720W FL-1 light uses much less electricity than a 1000W HPS light of the same light output. If both were running on average 12 hours per day, our LED grow light would save customers about $170 per light per year (will vary depending on local energy costs). Add on the fact that LEDs have a reduced heat output, meaning less energy is needed to be spent on cooling rooms in hotter regions, which increases savings even further. In total, the cost of energy savings of our LED versus the most commonly used light (1000W DE HPS Grow Light) is greater than $250 per light per year.

In summary, by switching to VOLT Grow®’s LED grow lights from traditional HPS fixtures, you can save at least $750 per light per year! For large facilities, this would save grow operations thousands of dollars. Investing in lighting equipment is a pivotal process for your cultivation that you only want to do once, which is why it is important to think about the long-term costs and maintenance, in addition to the light’s output.